Description

| Feature | Specification |

|---|---|

| Instrument Type | Microprocessor-based Flame Photometer |

| Measurable Elements | Sodium (Na), Potassium (K), Calcium (Ca), Lithium (Li) |

| Measurement Range | Na & K: 0–100 ppm; Ca: 0–100 ppm; Li: 0–50 ppm |

| Accuracy | ±2% of full scale |

| Display Type | High-resolution graphical LCD |

| Calibration Mode | Multi-point curve fitting with data storage capability |

| Ignition System | Automatic electronic ignition with flame monitoring |

| Detection System | Highly sensitive photodetectors and narrow-band interference filters |

| Flame Control | Manual and auto controls for air-fuel ratio |

| Data Handling | Stores calibration curves and test results; PC/printer connectivity |

| Safety Features | Built-in diagnostics, flame failure alarm, over-range indication |

| Power Requirement | 230V AC ±10%, 50 Hz |

| Body Construction | Chemically-resistant, powder-coated lab-grade housing |

| Software Features | Microprocessor-controlled analysis with automated result processing |

| Dimensions | Compact and space-efficient layout for bench-top use |

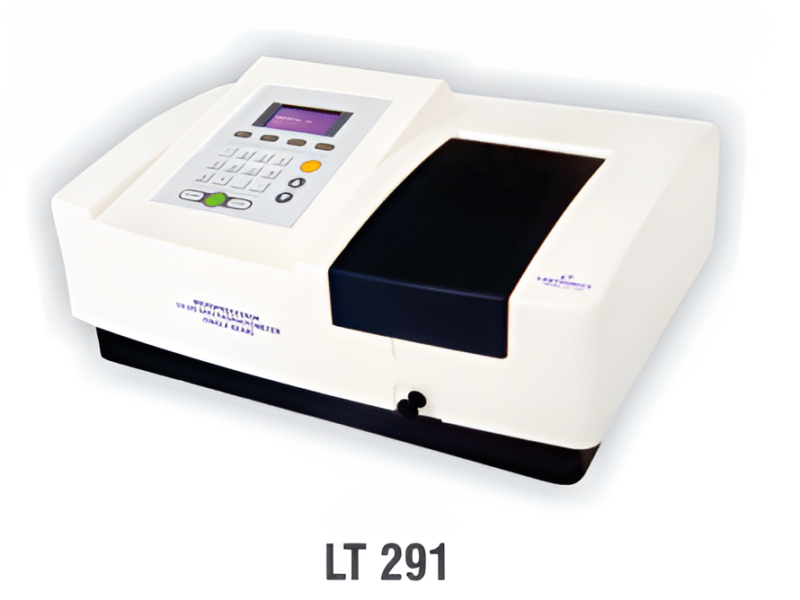

Product Overview – LT-672 Flame Photometer

The Labtronics LT-672 Microprocessor Flame Photometer is a precision-built instrument engineered to deliver accurate elemental analysis of alkali and alkaline earth metals, including sodium, potassium, calcium, and lithium. Designed for modern clinical, agricultural, pharmaceutical, and industrial laboratories, this model balances robust hardware with automated digital performance, enabling high-throughput and error-free analysis.

Precision Meets Efficiency

Using the flame emission spectroscopy technique, the LT-672 detects characteristic light emitted by metal ions in a flame and converts it into a digital signal. The microprocessor processes these signals to compute precise ion concentrations. This makes it ideal for detecting both trace elements and higher concentrations in clinical serum, fertilizers, food samples, and water testing.

Intuitive Display & Automated Operation

Its interactive LCD display allows users to visualize real-time readings, calibration progress, and operational parameters. The intuitive menu system, powered by an embedded microprocessor, guides even non-specialist users through calibration, measurement, and report generation with ease.

Multi-Point Calibration with Data Storage

With curve-fitting algorithms and multi-point calibration, the LT-672 ensures repeatability and accuracy. Calibration data and sample readings can be stored internally, making batch testing, comparative analysis, and documentation seamless—especially useful for GLP/GMP-regulated labs.

Reliable Ignition & Flame Control

The auto-ignition and safety interlock features simplify flame handling and enhance operational safety. Adjustable fuel-to-air ratios give users control over flame intensity, optimizing sensitivity for specific elements. Advanced filters and photodetectors reduce background noise and ensure accurate, interference-free measurements.

Built for Heavy Lab Use

Encased in a rugged, corrosion-resistant body, the LT-672 is ideal for heavy-duty daily use. Its compact size fits easily into most bench spaces, and its low maintenance requirements make it a cost-effective, long-term addition to any elemental analysis setup.

Connectivity & Compliance

Equipped with USB/RS-232 ports, the device can export results directly to computers or lab printers, allowing easy integration with LIMS or other documentation software. This helps maintain traceability and ensures compliance with industry reporting standards.

Built-in Safety Monitoring

The LT-672 includes real-time system diagnostics, flame status indicators, and error alerts—minimizing equipment downtime and operator risk. Its intelligent fault detection reduces the risk of measurement inaccuracy or equipment damage.