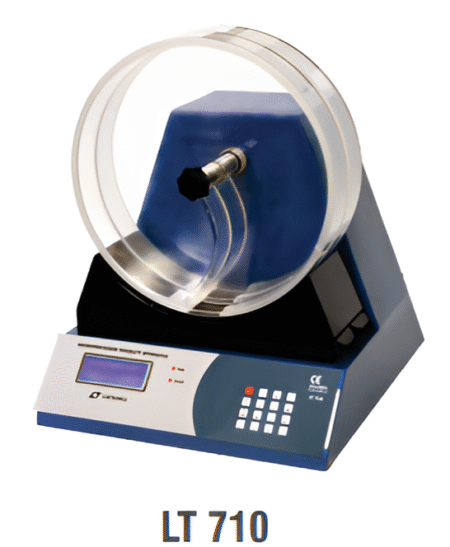

Description

| Feature | Specification |

|---|---|

| Model Number | LT-710 |

| Type | Microprocessor-Based Friability Tester (Double Wheel) |

| Number of Drums | 2 Transparent Acrylic Drums (mounted horizontally) |

| Drum Dimensions | Standard size as per USP/EP/ASTM standards |

| Display | Bright Digital LED Display |

| Control Panel | Soft-touch membrane keys with intuitive menu navigation |

| Drive Mechanism | Quiet, motor-driven mechanism |

| Timer & Revolution Control | Programmable duration and rotation count (up to 999 revolutions) |

| Accuracy | ±1 rotation |

| Power Supply | 230V ±10%, 50 Hz |

| Compliance Standards | Conforms to USP, EP, and ASTM tablet friability test standards |

| Body Construction | Durable, powder-coated metal with non-corrosive finish |

| Safety Features | Overload protection, automatic stop after test completion |

| Data Handling | Microprocessor memory for auto-calculation of revolutions and test duration |

Product Description with Detailed Overview

The Labtronics LT-710 Microprocessor Friability Apparatus is a premium dual-drum tablet testing system designed for rigorous mechanical stress analysis of tablets. Developed for pharmaceutical laboratories, research institutions, and industrial QC labs, this equipment ensures precision-driven performance, repeatability, and compliance with international standards.

Dual-Drum Design for Enhanced Throughput

The LT-710 features two transparent acrylic drums aligned horizontally. This configuration enables simultaneous testing of two tablet batches, significantly boosting efficiency without compromising accuracy. It’s an ideal solution for high-volume laboratories aiming to streamline quality control processes.

Intelligent Microprocessor Control

At the core of this system lies a smart microprocessor, responsible for real-time control of rotation speed, total revolutions, and test timing. It automatically calculates results, minimizing manual data entry and enhancing test consistency. With soft-touch membrane controls and a crisp LED display, operating the unit is smooth and intuitive—even for new users.

Built for Precision and Durability

The robust metallic enclosure is built for long-term performance in demanding lab environments. Its powder-coated, corrosion-resistant body protects internal components while maintaining a compact footprint—making it ideal for laboratories with limited bench space. The motorized drive system ensures silent, vibration-free operation to maintain sample integrity.

Regulatory Compliance and Accuracy

Complying with USP, EP, and ASTM friability testing protocols, the LT-710 guarantees reliable, audit-ready results. Whether testing coated or uncoated tablets, it provides critical insights into physical strength, handling resilience, and shelf-life reliability—key metrics for pharmaceutical production.