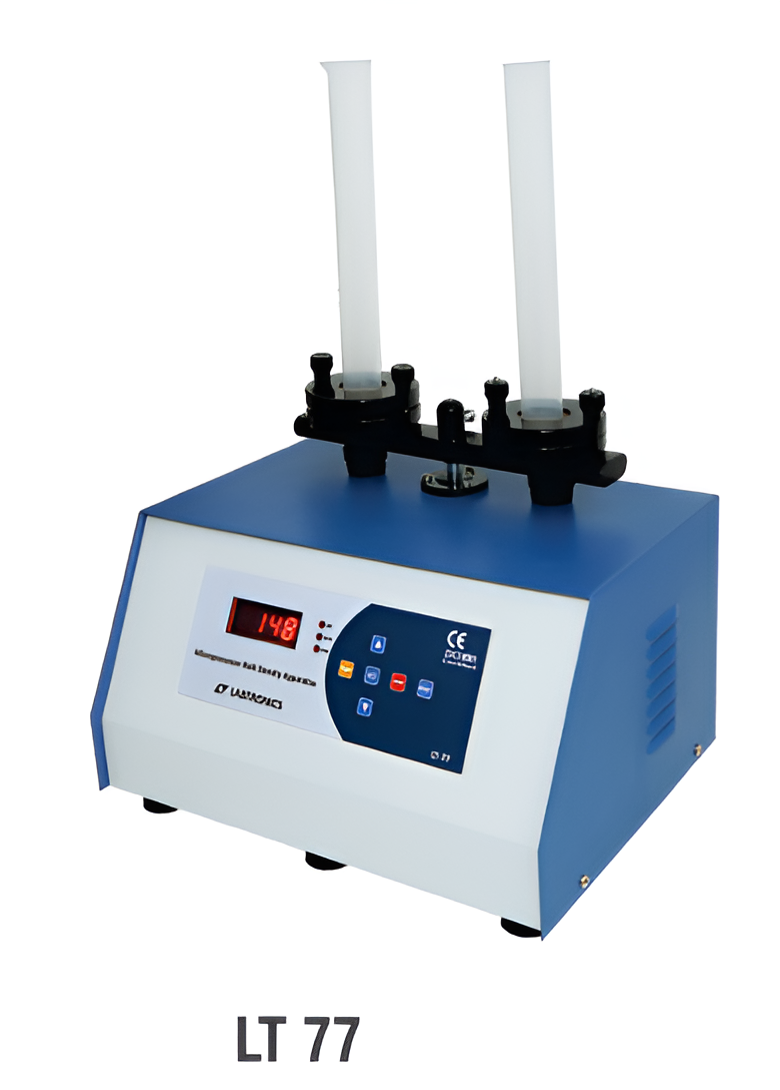

Description

| Parameter | Specification |

|---|---|

| Model | Labtronics LT-77 |

| Measurement Types | Bulk Density (Poured), Tapped Density |

| Tapping Mechanism | Electromagnetic, vibration-free |

| Drop Height | 25 ±1 mm (as per USP/Pharmacopeia) |

| Cylinder Compatibility | 100 mL & 250 mL graduated cylinders |

| Operation Modes | Single and dual-cylinder simultaneous operation |

| Cycle Count Control | Digital preset counter with adjustable tapping cycles |

| Display Interface | Digital LCD screen for cycle count, test status, and user inputs |

| Timer | Programmable digital timer for accurate cycle timing |

| Material Construction | Chemically resistant powder-coated steel with vibration isolation base |

| Power Supply | 230V ±10%, 50 Hz |

| Compliance Standards | USP <616> Method I & II, IP, BP, and other international guidelines |

| Data Output Options | USB/RS-232 interface for printer or external data logger integration |

| Dimensions | Compact benchtop design (approx. 400 x 300 x 250 mm) |

| Weight | Approx. 12–15 kg |

Product Overview

The Labtronics LT-77 Digital Bulk Density Apparatus is a precision-engineered instrument specifically built for measuring the poured and tapped density of powders and granules, a critical parameter in pharmaceutical, food, cosmetic, and industrial materials testing.

This apparatus plays a central role in formulation development, tablet manufacturing, and powder quality assurance, especially in solid dosage form production. Its ability to evaluate flowability, compaction, and volume consistency makes it indispensable for both R&D and regulatory compliance labs.

Accurate Density Measurement with Digital Control

Equipped with a microprocessor-based tapping system, the LT-77 enables standardized and repeatable testing by eliminating manual errors. The electromagnetic tapping assembly ensures that each tap conforms to pre-set drop height and frequency, resulting in consistent compaction of the powder mass. This feature is essential for maintaining test integrity and meeting pharmacopeial standards such as USP <616>, IP, and BP.

Dual-Cylinder Functionality for Enhanced Throughput

With its dual-cylinder compatibility, laboratories can run two independent tests simultaneously, doubling productivity. The cylinders, supported securely on a stable base, prevent displacement during operation, ensuring reliable data collection.

Digital Interface and Data Integration

The intuitive LCD control panel offers operators full command over tap count, timing, and operational settings. Data output ports (USB & RS-232) allow seamless integration with external printers or LIMS systems, ensuring traceable and auditable results for GMP/GLP environments.

Robust Design and Chemical Resistance

Crafted from durable, corrosion-resistant materials, the LT-77 withstands aggressive laboratory environments. The design minimizes external vibrations, safeguarding result accuracy. Its compact footprint makes it ideal for both teaching labs and high-throughput industrial testing facilities.

Suitable for Research and Training

The apparatus is not only built for industrial QC but also finds use in academic laboratories where students and researchers study powder mechanics, flowability, and material behavior. Transparent graduated cylinders enable easy visual observation of powder level changes during testing.

Common Applications

- Pharmaceutical industry – Bulk/tapped density tests for tablet and capsule formulation

- Chemical & material science – Evaluation of powder compressibility and flow properties

- Food & nutraceutical labs – Powder consistency and product formulation testing

- Cosmetic labs – Powder fill uniformity and blend evaluation

- Educational institutes – Hands-on learning in material characterization