Description

Specifications Table

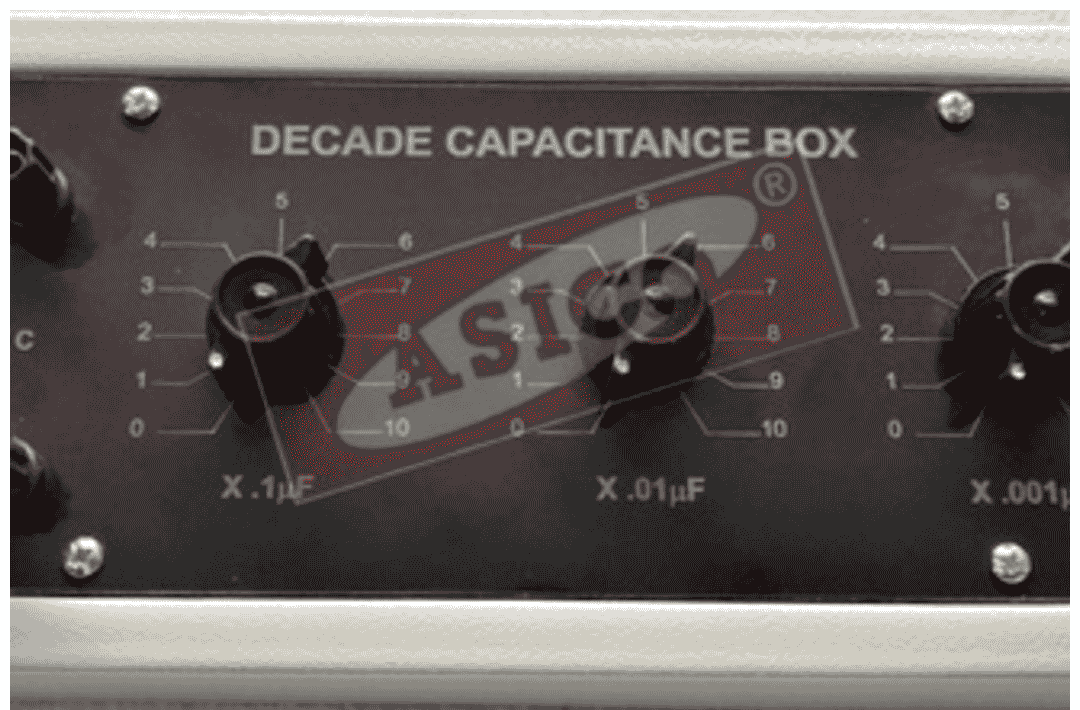

Product Material – High-quality glass and metal components

Grade – Educational/Research Grade

Application – Physics experiments, wave propagation studies

Product Overview

This complete ultrasonic wave velocity measurement setup for kerosene oil is designed for precise experimental physics work. The kit includes all necessary components to determine the speed of ultrasonic waves through kerosene oil with high accuracy. The apparatus features a durable glass container for the kerosene medium, coupled with a high-frequency ultrasonic transmitter and receiver system. The electronic components are carefully calibrated to ensure consistent wave generation and detection. The setup comes with clear measurement markings and stable mounting to prevent external vibrations from affecting results. All materials are selected for their chemical resistance to kerosene oil and durability under repeated use. The system is designed for easy assembly and disassembly, making it ideal for both demonstration and repeated experimental use. The included components are manufactured to strict quality standards to ensure reliable performance and accurate data collection for wave velocity measurements.

FAQs

1. What is the typical accuracy range for this ultrasonic wave velocity setup?

The setup is designed to provide measurements within ±1% accuracy under standard laboratory conditions when properly calibrated and used according to instructions.

2. Can this setup be used with liquids other than kerosene oil?

While optimized for kerosene oil, the setup can technically work with other non-viscous liquids, though the accuracy may vary depending on the liquid’s acoustic properties.

3. What power source is required for the ultrasonic components?

The electronic components typically require a standard 220-240V AC power supply, with the transformer included in the kit converting it to the necessary operating voltage.

4. How should the ultrasonic transmitter be positioned relative to the receiver?

The transmitter and receiver should be aligned parallel to each other with the liquid medium between them, maintaining equal distance from both sides of the container for optimal wave transmission.

5. What maintenance is required to keep the setup functioning properly?

Regular cleaning of the glass container with isopropyl alcohol, checking electrical connections for corrosion, and storing in a dry environment when not in use will maintain optimal performance and longevity.